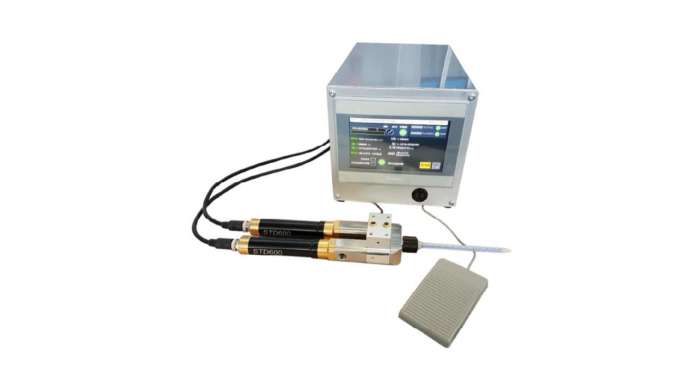

ISCRA dielectrics, a distributor specialized in fluid dispensing equipment, presents STD DUO 600, the most adequate solution for the microdosing of two-component epoxy resin, where high precision, reliability, versatility and repeatability are required.

In recent years, resins and adhesives have been increasingly used to soak, seal, glue, protect and isolate electrical and electronic components and more. The fields of application are various and the range of products is very wide. Alongside the single-component compounds, the two-component products have grown significantly. These systems are based on the combination of resin and hardener, which guarantee superior features.

After identification of the proper compound to use according the required application, it is very important to choose the correct dosing process to achieve a good final result both from the qualitative and economic point of view.

If the process of applying the single-component resin is fairly simple, as it is a single fluid, the preparation and dispensing of two-component liquids is more delicate. In particular, the proportioning and mixing of the two components are the most critical stages, with a higher risk of errors. Resin and hardener must be proportioned according to a well-defined ratio, indicated by the manufacturer (i.e. 1:1 – 10:1 – 4:1 etc.) and carefully mixed in order to avoid material waste and long production time. Mixing with the wrong ratio can cause the product to harden, resulting in waste in the manufacturing process.

For this purpose, the MMD (Meter Mix Dispensing) dispensers were created: easy-to-use precision equipment that proportionate, mix and dose in a reliable and repeatable manner.

For this purpose, the MMD (Meter Mix Dispensing) dispensers were created: easy-to-use precision equipment that proportionate, mix and dose in a reliable and repeatable manner.

The ideal equipment solution must however be customized according to the resin-hardener system and the application needed and it requires a partnership between the customer and the supplier.

A relatively difficult application is the microdosing process, required when it is necessary to deposit two-component resin doses in a very small space.

A constraint that normally forces the operator to perform a long and accurate filling job, constantly taking care to avoid the leakage of resin. The operation is usually performed completely by sight, with great time consumption and psycho-physical effort.

ISCRA dielectrics’ STD DUO 600

The STD DUO 600 device, proposed by ISCRA dielectrics, represents a valid solution that makes the whole process completely automatic, from proportioning to dosage, responding to the most demanding microdosing requirements.

STD DUO 600 is a volumetric dispenser with progressive cavitation pumps, driven by two brushless motors with encoder.

Programming is simple and fast, "user-friendly"; just set the fundamental parameters of the resin-hardener system in the device controller: resin/hardener volumetric ratio, unit volume per dosing cycle, dispensing speed, number of dosing cycles and the dispensing interval.

Once these simple parameters have been set, after an experimental test, it is possible to proceed with the production.

The result is to obtain a correct proportion of resin and hardener, to mix it carefully using a static mixer and, finally, to dispense in a completely automatic way the single doses necessary for the desired application without smearing, waste of material and time.

The STD DUO 600 technology makes it possible to dose a wide range of fluids, from those with very low viscosity (water, oils, etc.) to very viscous products (up to 1,000,000 Cps) such as greases, pastes, silicones , various sealants, two components resins - as well as additives with abrasive charges - ensuring a homogeneous and constant supply in every situation.