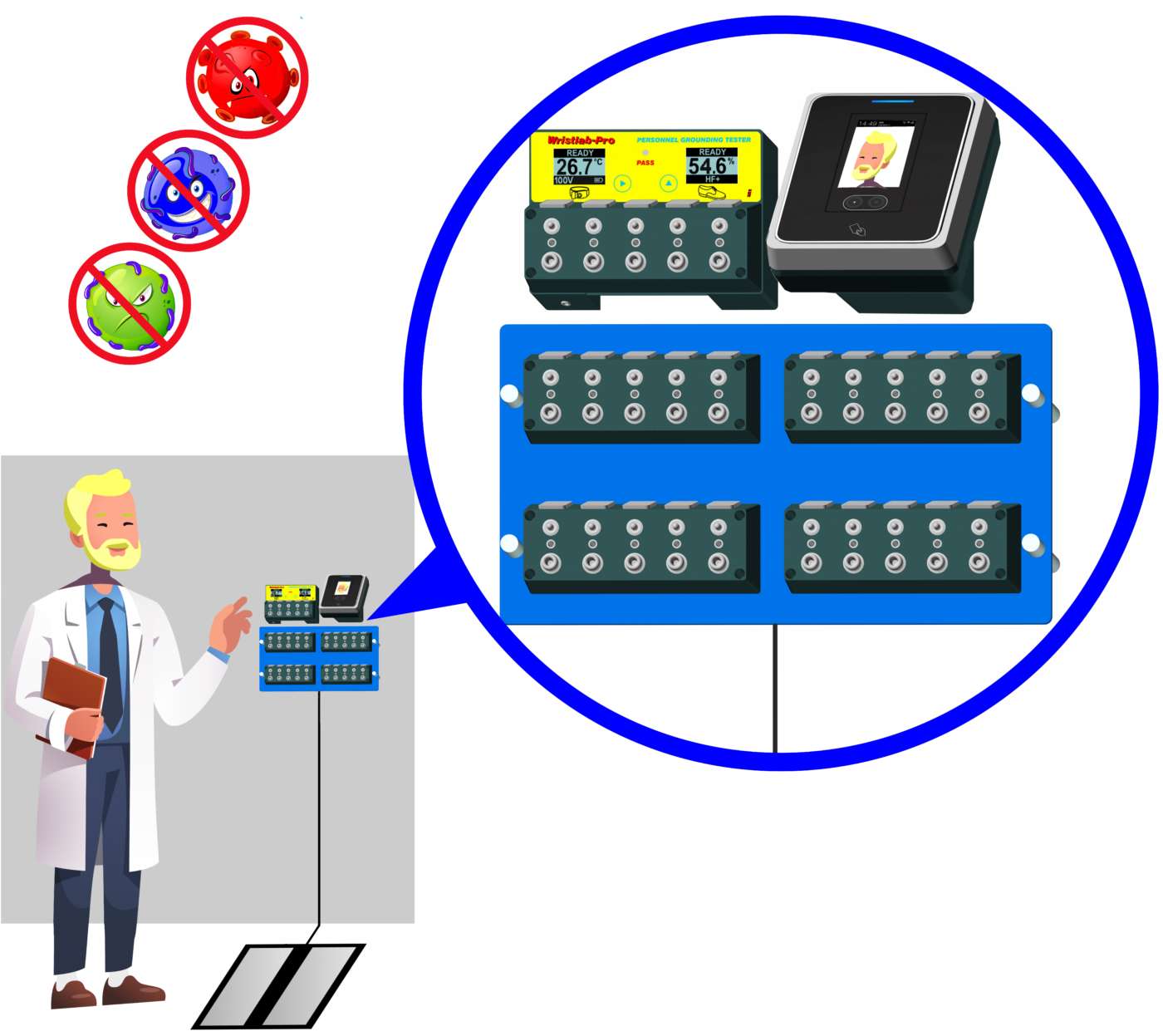

Designed to minimize biological risk, such as Covid-19, the new WristLab-Pro identifies the operator via RFID card or facial recognition

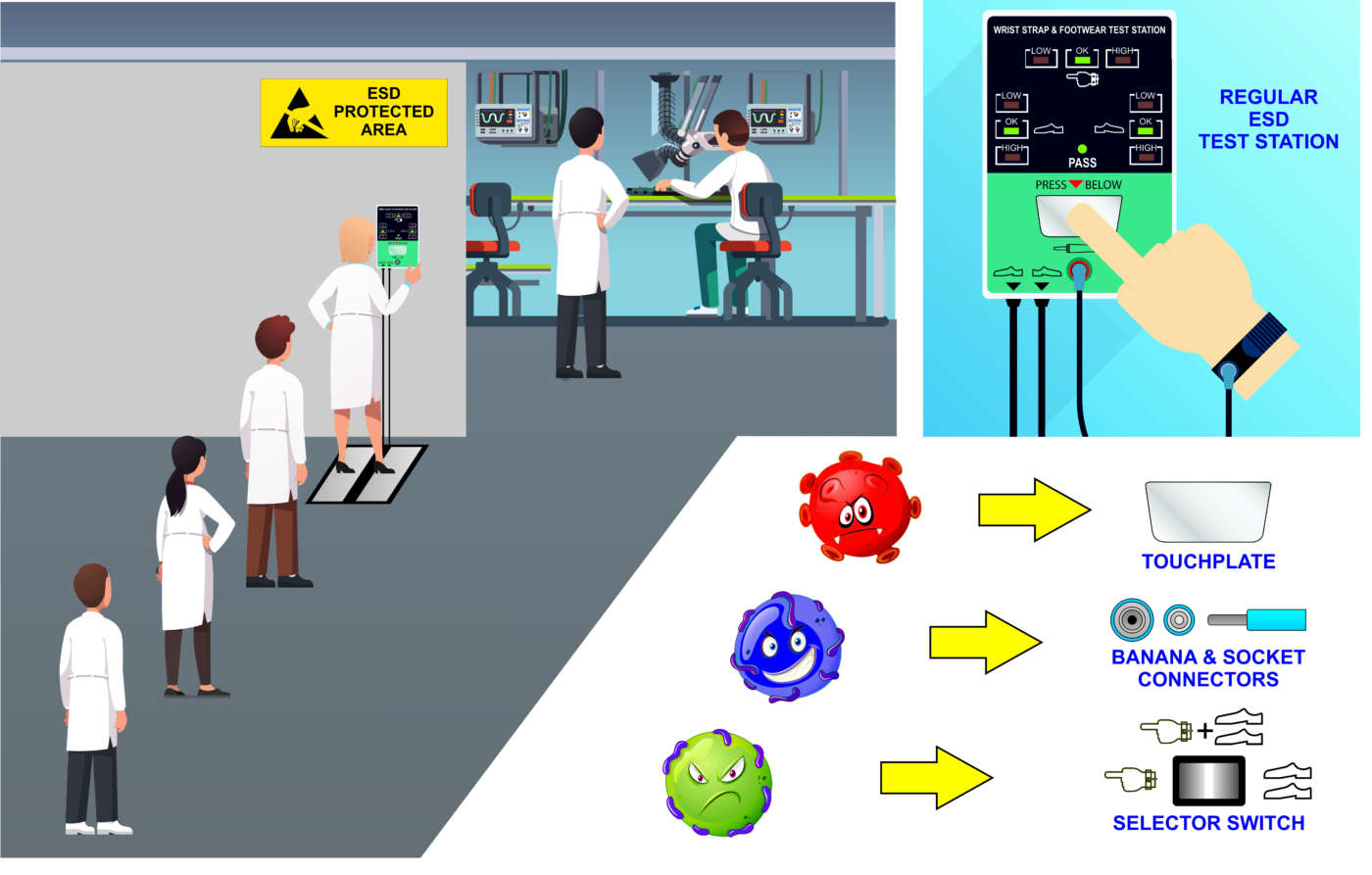

After the Covid-19 pandemic, for the ESD test stations has become evident the need tominimize the biological risk associated with the possible transmission of infections by indirect contact between people.

In common ESD test stations there are mainly three "infection ways" through which viruses, bacteria or other pathogens can infect operators:

- the touchplate, the high-voltage metal plate that everyone touches with their finger;

- the input connectors of the bracelets (banana socket and snap buttons);

- the instrument setting buttons or selectors.

The touchplate, connectors and buttons, should be disinfected after each different operator’s use.

The new Wristlab-Pro test station offers innovative and simple solutions to these new health needs.

In fact, each operator has his own personal touchplate and his own personal bracelet input connectors.

The Wristlab-Pro includes 5 separate inputs for 5 different operators.

Optional Expansion Unit modules can be added to the instrument to increase the available inputs.

The last "infection way" is the instrument setup buttons which usually are used by the operator to select the measuring mode suitable to him and to his specific tasks. In the design of the new WristLab-Pro we therefore tried to limit their use as much as possible, not only for health purposes, but also to speed up the access time to the EPA areas and to simplify the training of personnel in the use of the ESD test stations.

For this purpose, the Recognition Module option can be added to each Wristlab-Pro to identify the operator via RFID card or facial recognition. These recognition systems are both contactless and therefore with zero biohazard. The Recognition Module is capable to recognize up to 300 users and for every identified operator will be performed the measuring mode previously assigned. In practice, each operator is associated with a "profile" among the 10 available in total. The measuring mode, the lower and upper limits of the resistance, etc ... are specified in the associated profile.

The new WristLab-Pro test station through these 2 options (the Expansion Unit and the Recognition Module) can be configured to meet different needs and can also be expanded at a later time.

There are usually four measuring modes in the ESD test stations:

- ONLY WRISTSTRAP

- ONLY FOOTWEAR

- WRISTSTRAP & FOOTWEAR

- HANDS FREE (HF); the touchplate is not used, the measurement current flows from one foot to the other, and the sum of the resistances of the two shoes is measured.

WristLab-Pro's Hands Free Plus

The WristLab-Pro introduces an additional measuring mode called HANDS FREE PLUS (HF+). In the HF+ measurement, the operator initially tests the footwear in Hands Free mode and then decides whether to get off the platform and finish the test or insert the wriststrap connector and touch its own metal-plate in order to make a "WRISTSTRAP & FOOTWEAR" measurement. , where the value of the shoes is indicated individually and no longer by the total of the two.

HF+ offers a more flexible solution, under the responsibility of trained operator.

This innovative test station is 100% Made in Italy, developed by Iteco, a specialist in ESD measurement instrumentation since many years, and there is a patent pending on this new product.

Technical characteristics:

- It has a clear and intuitive interface. After testing, the left display shows the resistance measured on the wriststrap, while the right display shows the resistance of the footwear. If the test PASS, the LED in the center lights up green. On the other hand, if the test FAIL, the LED lights up red. A different beep is also emitted for PASS and FAIL.

- It has an embedded thermo-hygrometer to register the environmental RH/T values which are fundamental parameters to better evaluate the results of the measurements.

- It is compact (165x110x50 mm) and can work both connected to the mains or using a 9 V battery to allow portability (in this case the HF and HF+ modes are disabled due to their high energy consumption).

- It is fitted with 4 strong magnets to easily hook/unhook from any metal support. In a moment it can be fixed on a metal column support or on a wall where the quick coupling/release metal plate has previously been screwed.

- Measurement range of the wriststrap and each individual shoes is between 50 KΩ and 2 GΩ. The lower and upper thresholds can be set to any value included within the measuring range, in order to satisfy the requirements of the IEC 61340-5-1, ANSI S20.20, or Atex standard which wants 1 GΩ as the upper limit for the footwear. The measurement voltage is selectable to 50 V or 100 V.

- Relay output to control the opening of the access door to the EPA area.

Expansion Unit

These modules are used to increase the available entries by 20 unit/each. For example, by adding 3 of them, you get a total of 60 extra entries available, in addition to the 5 embedded in the instrument, which could be reserved for convenience to external visitors. The Expansion Units are elegant blue panels; above each entry there is a suitable space to fit a sticker with the name or identification number of the associated operator.

They are spaced from the wall so that all the connecting cables can pass comfortably and hidden behind them.

Recognition Module

By adding this option, the operator can be recognized by card or by facial recognition. The Module has a 3.2" touchscreen display and is capable of recognizing up to 300 users.

The cards supported by its internal RFID reader are all EM cards and optionally even the Mifare.

Facial recognition uses two high-definition infrared cameras that allow identification even in low light conditions.

It is functional to all users regardless to their skin complexion, facial expression, beards and hairstyles, and the possible presence of the mask.

The Recognition Module complies with the General Data Protection Regulation (EU) 2016/679 (G.D.P.R.), in fact this biometric device uses a special algorithm (BioNANO) to encrypt biometric data in a non-reversible way.

The Module connects to the company LAN via RJ45 cable or Wi-Fi and is supplied with the EPA Access Manager software.

It should be noted that the Recognition Module and the WristLab-Pro station continuously work even during a temporary disconnection to the LAN network and they don't require any PC server software always running. All the access data are in fact stored internally in the Recognition Module and the EPA Access Manager software is used only occasionally to configure the system and download the access reports.

EPA Access Manager

The software and all its future upgrades are freeware. It is included in the Recognition Module option and requires Windows 10/8/7/XP to run.

It allows to:

- Save a report file of the accesses to the EPA area (date and time, RH/T, operator, resistance values etc.) in order to monitor the validity of the personal protection equipment over time.

- Import/export the biometric and RFID card data of all operators for backup use or to duplicate them on different test stations. The same operation can be done directly at the Recognition Module with a USB key.

- connect to different Recognition Modules and their associated WristLab-Pro stations, in order to manage different access points with a single application.

All operations performed by the software occur in the background. So far the test station can continue to enable accesses even during the download of the access report to the PC.