With the renewed brand, WellerErem expands the already vast choice of precision tools with a further 23 models; characterized by careful construction, they are robust and ergonomic. To date there are 263 and they cover all gripping, cutting, shaping and positioning applications. Made with Swiss quality, they are robust, long lasting and highly accurate

Erem was founded in 1963 in Geneva (Switzerland), at that time it was an artisan production of cutting tools, pliers and tweezers, of the highest quality and precision, becoming a world leader in its sector within a few years. In 1993 it joined the Cooper Industries family, which also includes the Weller brand, world leader in soldering and reworking equipment in electronic applications. In 2010 both companies became part of APEX TOOL GROUP (ATG), born from the joint-venture between Cooper Tools and Danaher Tool Group. In 2014 the production moved to Bevaix, from Yverdon, where it was established in 1972; both cities are a few kilometres away, with a wonderful view of Lake Neuchâtel.

2020 marks an important step, with the rebranding in WellerErem. ATG's strategy is, in fact, to have under the same Weller umbrella all those ATG brands that also belong to the world of hand soldering, which are: Weller Professional soldering (recognizable by the light blue products); Weller Consumer soldering (recognizable by the red color); Precision Tools covering Weller Erem and Weller Xcelite. All renewed brands that keep the synonym of high quality tools, precision and reliability unchanged, which, in the case of WellerErem, is also underlined by the seal "Made in Switzerland"

Cutters

The cutters are available with three different cutting levels, depending on how "clean" the surface of the processed material must remain: the versions with "semi flush" cut leave a rounded surface that is not perfectly flat (less than 0.5mm), but not sharp, unlike the “flush” cut, it leaves a very fine burr on the lead. For applications that require a perfect cut that does not leave any burrs or cracks (which can become, for example, an access route for oxidation), there are also wire cutters with "super full flush" cut, practically clean (mainly required in the sectors aerospace and medical). Even the shape and size of the "heads" are varied, to try to satisfy personal needs and preferences: maxi, medium and small, rounded, tapered, low profile, straight (side cut) or inclined. Obviously, according to the precision of the cut and the shape and size of the head, the cutting capacity changes, inversely proportional to accessibility and visibility. In all cases, the quality of Weller Erem cutters starts from four cornerstones:

1 – the material is extruded, not moulded and the heads are hardened by means of an induction heating process to ensure strength and durability;

2 – the patented “Magic Spring” spring system guarantees precision and repeatability of the opening and closing movements and the constancy of the actuation force, thanks to this mechanism we can constantly reach a million cycles;

3 – locking system to prevent the overlapping of the blades;

4 – all handles have ESD coatings and have a fixed maximum opening, to avoid excessive user fatigue.

The wire cutters can be re-sharpened up to a maximum of three times; The service is free. There are many special versions, both for electronic and medical applications: cutters with storage tank for the cut material; with low profile head for cutting the pins of fine pitch SMD components; for the preparation of stents, which do not leave potentially very dangerous smudges; for cutting Kevlar, Vectran, optical fibers or very hard wires; solutions with fixed or adjustable spaced cut and many other special and customizable versions. In all the cutters it is possible to add the accessory that prevents the cut material from jumping dangerously away. A pneumatic tool with interchangeable heads is also available for the most repetitive applications; also in this case the heads can be re-sharpened for free.

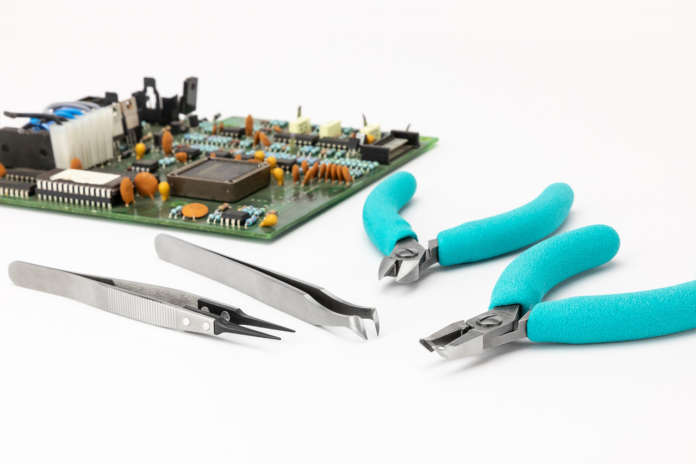

Pliers and Tweezers

Same basic technical solutions for the pliers (Magic Spring, spring, maximum fixed opening, head reinforcement, ESD handles...) and also in this case they are available for various applications: in addition to the classic handling, bending and preforming, there are versions with nylon coating to prevent scratching of the manipulated surfaces, wire stripping pliers (front or side, AWG 18-42), versions with “smooth” or knurled jaws for greater grip, with flat or rounded heads.

The different shapes and coatings of the handles of the cutters and pliers are aimed at improving working comfort, avoiding inflaming the carpal nerve, which could lead to very annoying consequences.

The range of tweezers is also very wide and is mainly aimed at the electronics, medical, aerospace, biology, jewellery, dental and watchmaking markets. Tools manufactured in different materials, according to the application: robust and rustproof non-magnetic stainless steel; special Erem stainless steel which is like the previous one, but more robust and resistant to acids and heat up to 300 °C; hardened steel to increase its resistance, magnetic and not anti-rust; titanium for maximum lightness and resistance to high temperatures; brass so as not to damage the parts that are handled.

Some applications require synthetic or ceramic and non-metallic tips. Inside, the sealing part can be smooth or knurled for a better grip and, depending on the application, they are pointed, rounded, square, "enveloping" for small wires and, more generally, straight or inclined. To complete the range there are flat tweezers, coated in polyester, to manipulate, without damaging, wafers of silicon, gallium arsenide or titanium; wire stripping tweezers (AWG 30-40), to extract contacts, or cutting (to cut copper braids, small wires ..). Many tweezers in the catalog (but not all) can be equipped with a “padded” handle: in addition to being softer to the touch and heat resistant, they make the tweezers ESD.

"As more and more than words we prefer to let facts speak and the best way to evaluate the quality, precision, durability and reliability of these tools is to test them personally: those who try them are unlikely to come back! "Is the invitation of Walter Chiara, Director of APEX TOOL.