SEHO Systems GmbH will focus on equipment productivity in Hall 4, Stand 141 at the upcoming SMT/Hybrid/Packaging show, scheduled to take place June 5 - 7, 2018 at the Messe in Nuremberg, Germany.

Automation solutions

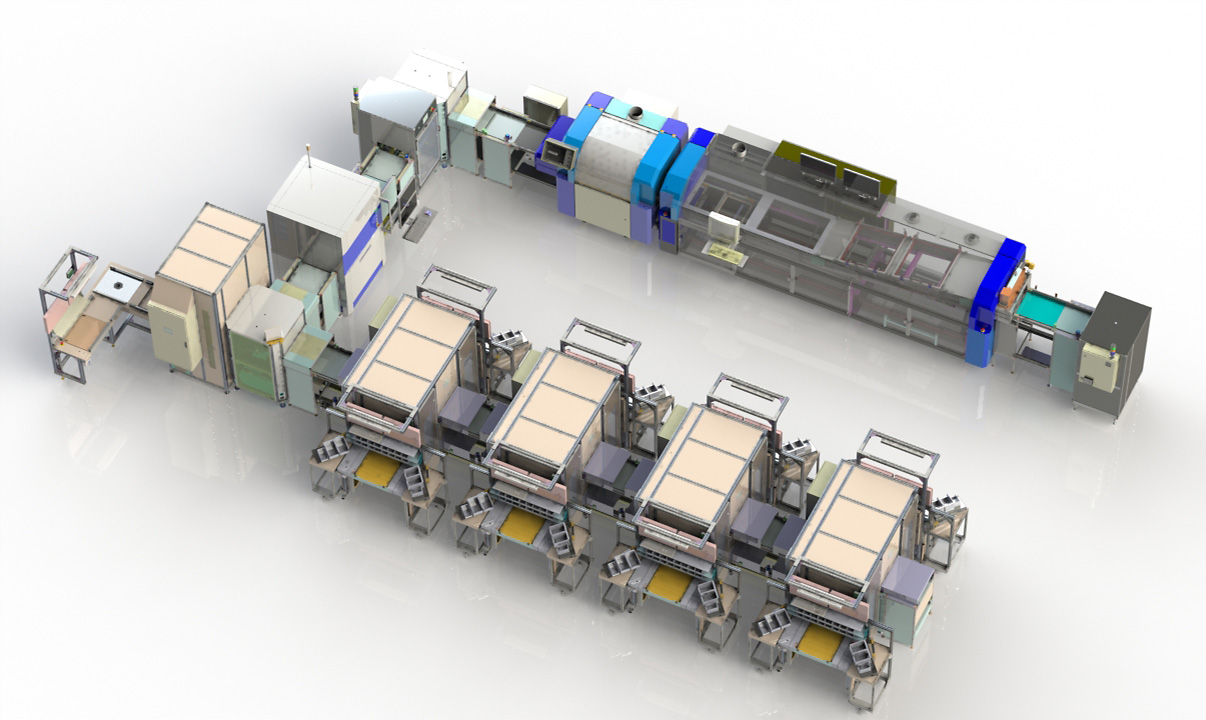

With the aim to make the production process in electronic manufacturing more efficient and to reduce production costs sustainably, SEHO extended its range of automation solutions in recent years. The products range from board handling with conveyor systems to connect various machines and work places in production lines, buffer systems, turn stations, e.g. for changing the direction in manufacturing lines, lift stations, as well as transfer units and many more.

Robots and cobots inline…

Work places are ergonomically designed and individually adjustable in height to be adapted to different operators. All of the connected stations such as buffers or conveyors adjust their height automatically. In addition, a particular focus is on cobots and robots that are housed in a multifunctional production cell. This cell can be equipped individually so that the robot may take over several tasks: for component placement, for assembly and disassembly of component downholders, for loading and unloading of carriers, for precise positioning of boards for AOI and electrical tests, and for removal of reject parts.

…combined with the soldering system

Combined with the soldering systems from SEHO, users benefit from complete solutions that are perfectly matched both technically and in regards to production flow.

A brand new SEHO PowerSelective

At the show, SEHO also will introduce the completely redesigned flagship PowerSelective for the first time. This selective soldering system offers the highest flexibility at simultaneously large production volumes with minimum footprint requirements. The latest generation of PowerSelective presents itself with many new features, including a gripper system that automatically can be turned 360° thus leading to remarkable cost savings in multi-wave processes, or an integrated AOI system that ensures reliable soldering results without influencing cycle time.